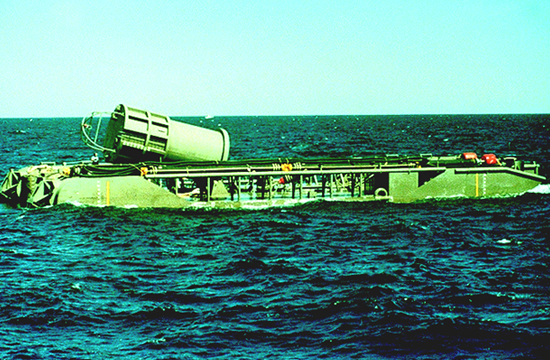

RA-DE SALM® – Units #2 – #7

Scope of Work

SOFEC designed, fabricated and tested each of these units to identical specifications. Various critical components are completely interchangeable to simplify logistical support requirements. Systems are designed for use under the variety of conditions that exist in likely theaters of application worldwide.

System performance was tested and proven by model testing and training exercises that were conducted in association with the No. 1 unit. Testing consisted of model basin towing tests, swivel performance testing and installation/deployment testing. Flowline deployment and performance was also proven and tested in conjunction with NAVSEA personnel training prior to declaring the systems operationally ready.

SOFEC technology for design and installation of SALMs formed the basis of this innovative concept.

General Description

| Client Name: | Naval Sea Systems Command (NAVSEA) |

| Contract Awards: | 1986 - 1992 |

| Completion Dates: | Completed consecutively and placed in service |

| Application: | Import Fuels |

Project Specifications

| Water Depth: | 11 - 61m (35 - 200ft) |

| Tanker Size: | 70,000 dwt |

| Dimension - Buoy: | 4.7mØ x 9.1m |

| Swivel: | Piggable, dual-product, 740 psig operating |

| Floating Hose: | 2 x 6-in. |

| Flowline Hose: | 2 x 6-in. Flexible reeled submarine pipeline 8 Reels each with 914m (3,000ft) totaling 7,310m (23,980ft) |

| Hawser System: | 12-in. Single grommet |

| Anchor Leg System: | Single anchor leg chain 3.5-in. Stud link ORQ adjustable length with chain swivel |

| Anchor System: | Gravity base 16.5m x 43.6m |

Comments

The systems were designed to be quickly adjustable to the site-specific water depths by altering the make-up of the single anchor leg chain assembly. The gravity base and the penetration of its shear keys into the seafloor provided anchoring to the seafloor. No heavy lift equipment is required to deploy or recover the systems.